Mechanical Engineering

Heavy plate for mechanical engineering

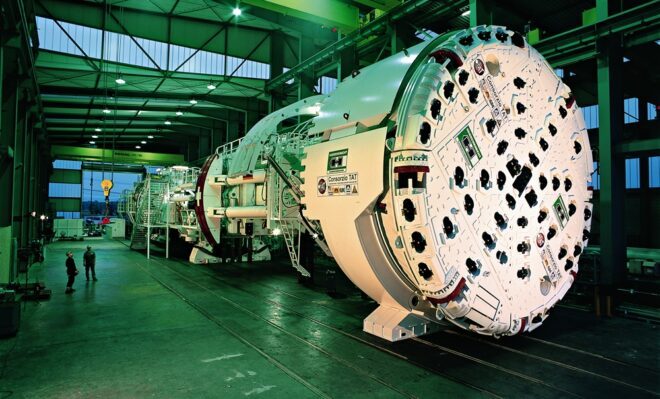

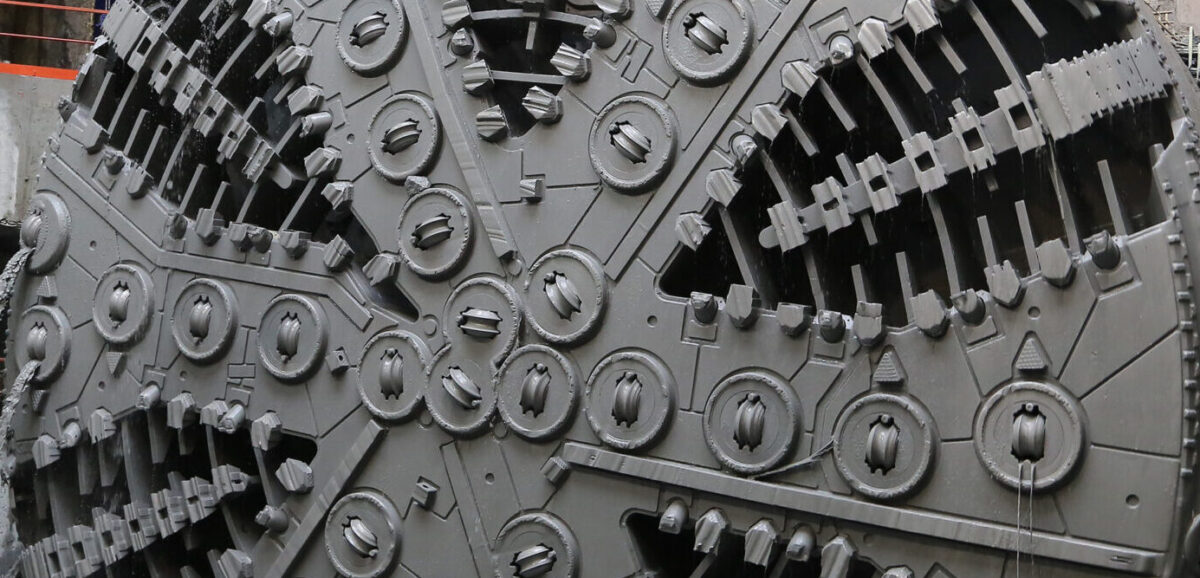

Heavy-duty presses, tunnel-boring machines (TBMs) and rolling-mill technology – for challenging tasks like these, you need a partner that will supply you flexibly and reliably, in perfect harmony with the needs of your specific project. This is why Dillinger is the top address for mechanical-engineering specialists when they need heavy plate.

Dillinger’s strengths in mechanical engineering

- We have consistently invested in the expansion of cost-efficient production facilities for thick and large-format plate, and are continuing to extend our market lead in this field with still more investments.

- Extra heavy precision-cut plate, individual specifications, or flexibility on delivery dates – we meet your requirements dependably, making your projects more accurately calculable.

- If you wish, we can semi-fabricate your order, and supply, for example, precisely fitting cut plates.

- Our long-established customers value constant and reliable contacts at both commercial and technical level. This creates the basis for mutually confident cooperation and joint optimisation of the supply partnership.

- Our customers also appreciate our future-orientated, long-term supply partnerships, with supply logistics, support and service all jointly harmonised with their specific needs.

Heavy-plate products

Downloads

Customer information

Verification of the content of inspection documents/inspection certificates of Dillinger

09.07.2021

Customer information concerning types of inspection documents as per EN 10204

02.11.2018

Electronically signed inspection documents 3.2 of Dillinger Hütte and their transmission

02.11.2018

Data sheets & specification

DILLIMAX 690 – High strength fine grained structural steel, quenched and tempered

24.01.2024

DILLIMAX 890 – High strength fine grained structural steel, quenched and tempered

24.01.2024

DILLIMAX 965 – High strength fine grained structural steel, quenched and tempered

24.01.2024

DILLIMAX 890 – High strength fine grained structural steel, quenched and tempered

24.01.2024

DILLIMAX 550 – High strength fine grained structural steel, quenched and tempered

19.01.2017

DILLIMAX 500 – High strength fine grained structural steel, quenched and tempered

26.10.2016

DIPLAN – Heavy steel plates with improved flatness tolerances over the entire plate dimension

29.06.2016

P420M HT – High strength fine grained structural steel, thermomechanically rolled, for high temperature application

29.06.2016

Processing instructions

Contact persons

Christoph Dickmann

Head of Sales Department, Machinery & Construction Equipment, Protection Steel

Phone: +49 6831 472385

Fax: +49 6831 47992681

E-Mail

Johannes Klemm

Head of Marketing & Technical Support, Machinery & Construction Equipment, Steel & Service Center, Plate Processing

Phone: +49 6831 475658

Fax: +49 6831 47999036

E-Mail