Case-hardening & quenching

& tempering steels

Perfectly harmonised hardness

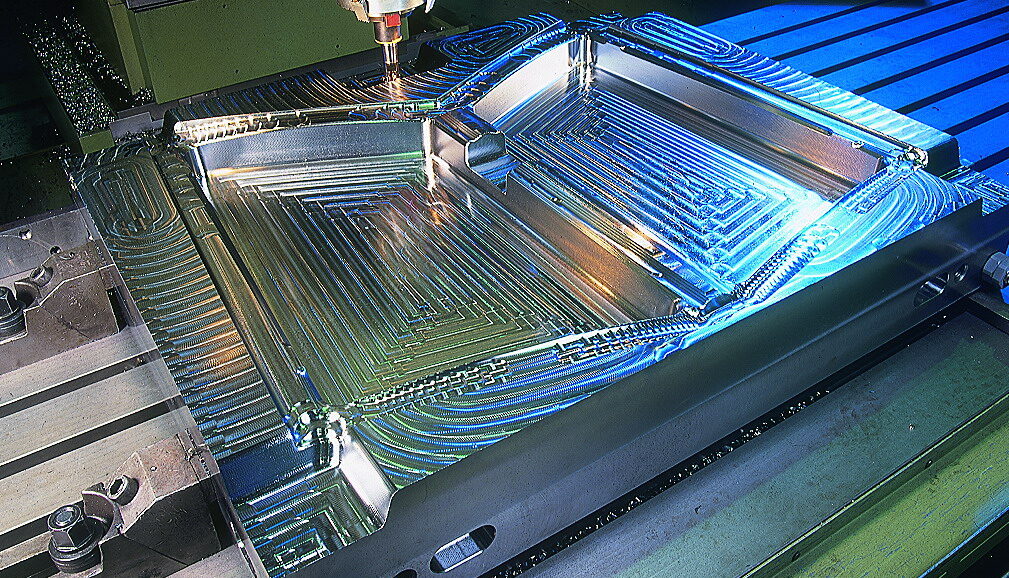

Tough inside and hard outside, to assure high wear-resistance – these are precisely the properties that Dillinger’s case-hardening steels give your components, such as sophisticated pre-cast concrete moulds, for example. Our quenching and tempering steels convince users with their strength, toughness and hardness – tailor-made for your application, for use, for example, in plastics mould-making.

The Dillinger range for your needs

- We supply non-alloy and low-alloyed case-hardening steels in conformity to EN 10084, and non-alloy and alloyed quenching and tempering steels in conformity to EN 10083, or in accordance with the US ASTM A829 and ASTM A830 standards.

- These steels, delivered in stress-relieving annealed state, have high cleanness, a homogenous structure, low proneness to distortion, and a uniform hardness distribution.

- You benefit from good chip-removing machinability, geometrical stability and minimised tool wear.

Useful information on case-hardening and quenching and tempering steels

Case-hardening steels have a carbon content of 0.10 % to 0.20 % and are intended for case hardening. This process generates greater internal toughness and significantly greater hardness on the material’s surface, and thus greater resistance to wear.

Quenching and tempering steels have a carbon content of 0.3 % to 0.6 %, and achieve their special properties only thanks to quenching and tempering, a heat treatment consisting of hardening and tempering. This process boosts the steel’s mechanical strength, toughness and hardness, each of which can be optimally adjusted by selecting the correct tempering parameters. Alloying-element (chromium, manganese, molybdenum and nickel) contents are precisely calculated to match the specific application. This is of particular importance in the case of greater plate thicknesses, which are required, above all, in moulds for the processing of plastics.

Proprietary steels

Applications

Contact persons

Christoph Dickmann

Head of Sales Department, Machinery & Construction Equipment, Protection Steel

Phone: +49 6831 472385

Fax: +49 6831 47992681

E-Mail

Johannes Klemm

Head of Marketing & Technical Support, Machinery & Construction Equipment, Steel & Service Center, Plate Processing

Phone: +49 6831 475658

Fax: +49 6831 47999036

E-Mail